I、Products Features

1, the initiative to send wire motor all use high-precision encoder of DC servo motor, the use of stepper motor as the wire feeding mechanism of the servo tension device has the following advantages:

A, low noise, high stability, high precision, high speed, high speed, from 0 to the highest speed can be completed within 0.5S;

B, high torque, so that the tension range, simple selection;

2, tension stability, acceleration deceleration process tension change is small, follow good performance.

3, tension control using electronic control drive, just press the button to adjust the tension increase or decrease.

This equipment has two sections of tension function, through access to the air source to achieve the two tension control.

Note: This is the 2 section tension tension device, no air tension indicator dial 0-5 range, the gas can work in the range of 0-10. If by changing the spring 0-5 can meet the customers, so do not have to connect with.

二、Specification parameter list

1.product type performance parameter table

|

Product model |

Maximum linear velocity |

Tension range |

Reference line range |

Tension bar |

|

ST800 |

18m/s |

3-800g |

0.02-0.4mm |

TR-25#-140 TR-25#-200 TR-26#-120 TR-26#-150 |

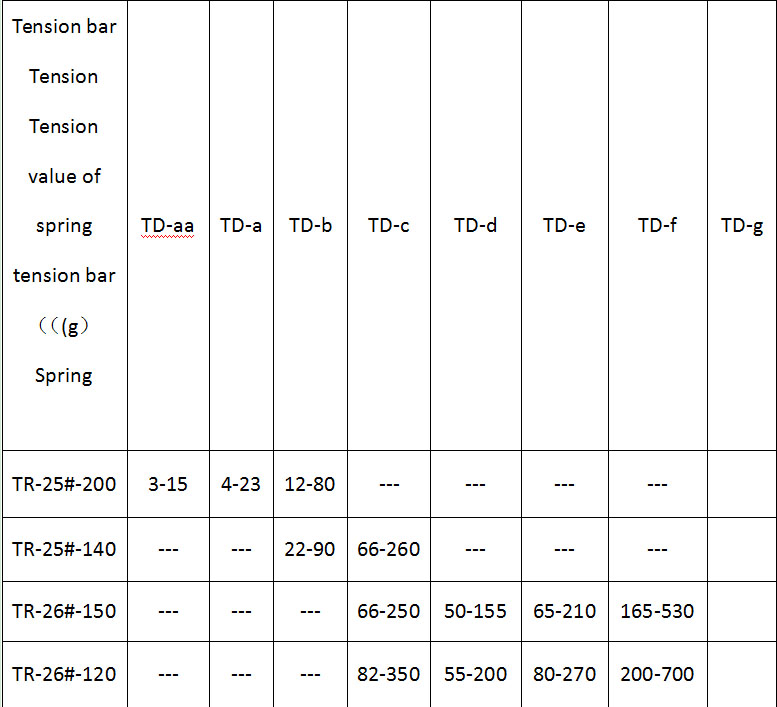

2, tension bar - spring tension value (g) range

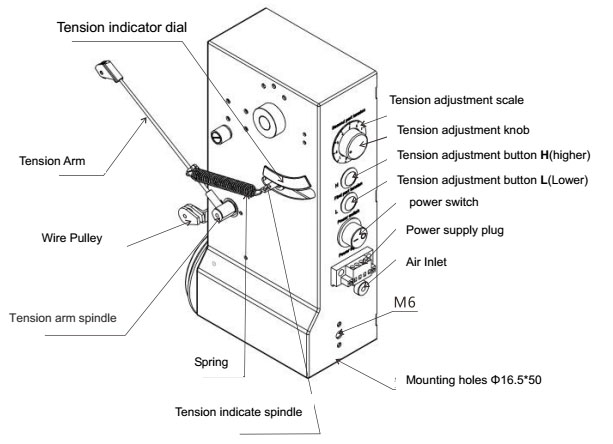

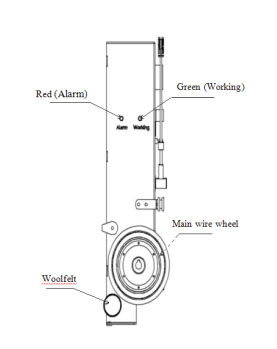

三、Product Diagram

四、Using instructions

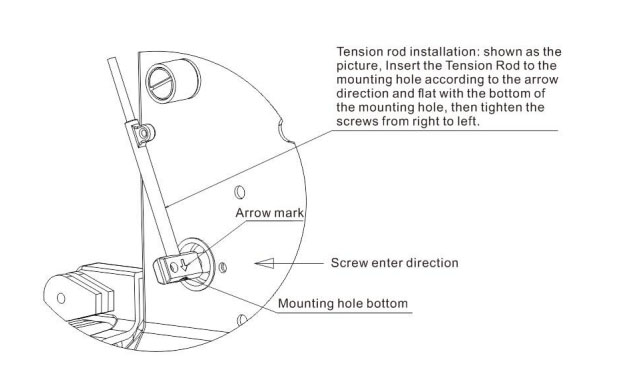

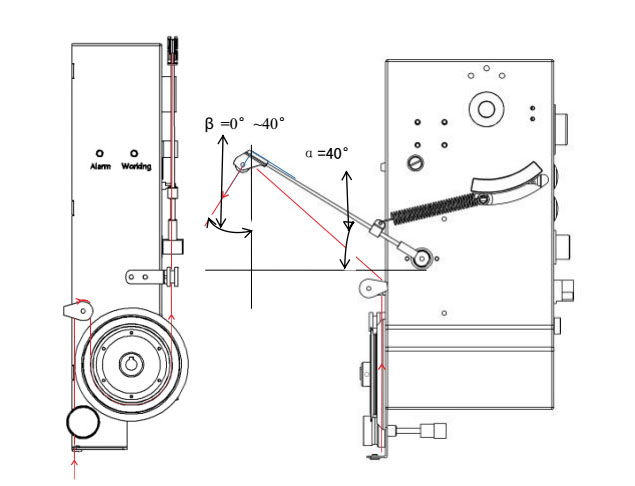

1, installation: the installation hole of the product is installed in the phi 16 columns, and the locking Wuxing handwheel; tension rod tension rod will be in accordance with the transfer shaft axis and the direction of the arrow into the flat, rotating the tension rod so that the spring hook is in the appropriate position, the locking screw (see Figure four).

2, power socket (Power input) connected to the DC36~48V power supply (see Figure five), the red line for the power supply, black line power supply negative.

3, through the air inlet (lnlet) to connect the gas source, gas pressure shall not exceed 0.6MPa (access to the trachea specification: Phi 4mm). Be sure to turn off the gas supply before turning the tension adjustment knob to allow the cylinder to reset. 4, hanging line: turn off the power switch (Power switch), according to figure five, the order of the line, while adjusting the tightness of wool felt to the wire in the wire wheel is not suitable for slipping. Proposed working time line and the tension bar into 90 degrees angle.

5, open the power switch (Power switch): press the button 1 to open (red light), press the button for the 0 off.

6, tension size adjustment (Tension adjustment) (as shown in Figure 1): Turn off the gas source, rotate the tension adjustment knob, the corresponding scale value of the greater the greater the tension, or vice versa; get the corresponding tension value, you can refer to the scale of the tension indicator scale mark.

7, indicator: This product has 2 indicator light: Break state: red light Standby: green light Working status: green flash

五、Note

1, ST800 series single rated current is 2.7A, maximum 4A; must be used to stabilize the power supply DC36~48V

Please use the power supply and the general cable, pay attention to the safety of electricity.

2, the use of ST800 products, adjust the tension must be closed before the gas source, and then rotate the tension adjustment knob; normal work, not allowed to adjust the tension.

3, the initial thread or accidental break back line, please turn off the power switch, then hanging line; as in line caused by misuse of the main wire feeding wheel winding the enameled wire coil, switch off the power switch of the tension device then wound cleaning line.

4, each time the line to check the tightness of wool felt and adjust the tightness of wool felt to the wire in the wire feeding wheel does not slip for the right to the wire in the delivery line is not suitable for skidding.

5, alarm, fault signal output: broken line or alarm state, relay output off; in normal state, the relay output.

6, the line method and the corresponding angle of the corresponding installation position, please refer to figure four.

7, this product is electrical products, please pay attention to waterproof moisture-proof.

六、Tension Rod installation and hanging wire diagram