|

Item |

Name |

Model No.(mm) |

|||||||||

|

L |

L1 |

D |

D1 |

d1 |

d2 |

H |

|||||

|

R2 Series |

|||||||||||

|

1 |

R2-001 |

RN0326-2-1006 |

26 |

6 |

2 |

1.0 |

0.3 |

0.6 |

--- |

||

|

2 |

R2-002 |

RN0326-2-0806 |

26 |

6 |

2 |

0.8 |

0.3 |

0.6 |

--- |

||

|

3 |

R2-003 |

RN0330-2-0807 |

30 |

7 |

2 |

0.8 |

0.3 |

0.4 |

--- |

||

|

4 |

R2-004 |

RN0326-2-1006 |

26 |

6 |

2 |

1 |

0.3 |

0.6 |

--- |

||

|

5 |

R2-005 |

RN0330-2-0807 |

30 |

7 |

2 |

0.8 |

0.3 |

0.4 |

--- |

||

|

6 |

R2-006 |

RN0330-2-0810 |

30 |

10 |

2 |

0.8 |

0.3 |

0.4 |

--- |

||

|

7 |

R2-007 |

RN0530-2-1008 |

30 |

8 |

2 |

1 |

0.5 |

0.5 |

--- |

||

|

8 |

R2-008 |

RN0535-2.5-1411 |

35 |

11 |

2.5 |

1.4 |

0.5 |

0.8 |

--- |

||

|

9 |

R2-009 |

RN0635-2-1610 |

35 |

10 |

2 |

1.5 |

0.5 |

0.8 |

--- |

||

|

10 |

R2-010 |

RN0535-2.5-1210 |

35 |

10 |

2.5 |

1.2 |

0.5 |

0.8 |

--- |

||

|

11 |

R2-011 |

RN0530-2-1208 |

30 |

8 |

2 |

1.2 |

0.5 |

0.8 |

--- |

||

|

12 |

R2-012 |

RN0830-2 |

30 |

|

2 |

2 |

0.8 |

0.8 |

--- |

||

|

R3 Series |

|||||||||||

|

1 |

R3-001 |

RN0330-3-1007 |

30 |

7 |

3 |

1.0 |

0.3 |

0.8 |

--- |

||

|

2 |

R3-002 |

RN0330-3-0807 |

30 |

7 |

3 |

0.8 |

0.3 |

0.6 |

--- |

||

|

3 |

R3-003 |

RN0430-3-1210 |

30 |

10 |

3 |

1.2 |

0.4 |

0.6 |

--- |

||

|

4 |

R3-007 |

RN0530-3-1311 |

30 |

11 |

3 |

1.3 |

0.5 |

0.8 |

--- |

||

|

5 |

R3-008 |

RN0323-3-1007P |

23 |

7 |

3 |

1 |

0.3 |

0.8 |

16 |

||

|

6 |

R3-009 |

RN0514-3-1509P |

14 |

9 |

3 |

1.5 |

0.5 |

0.6 |

6 |

||

|

7 |

R3-010 |

RN0311-3-1006P |

11 |

6 |

3 |

1 |

0.3 |

0.6 |

5 |

||

|

8 |

R3-011 |

RN0530-3-1455 |

30 |

5.5 |

3 |

1.4 |

0.5 |

0.6 |

--- |

||

|

9 |

R3-012 |

RN0330-3-1535P |

30 |

3.5 |

3 |

1.5 |

0.3 |

0.5 |

13 |

||

|

10 |

R3-013 |

RN0330-3-1012 |

30 |

12 |

3 |

1 |

0.3 |

0.6 |

--- |

||

|

11 |

R3-014 |

RN0821-3-2015P |

21 |

15 |

3 |

2 |

0.8 |

1 |

6 |

||

|

12 |

R3-015 |

RN0615-3-1505 |

15 |

5 |

3 |

1.5 |

0.6 |

0.6 |

--- |

||

|

13 |

R3-016 |

RN0530-3-2014 |

30 |

14 |

3 |

2 |

0.5 |

0.5 |

--- |

||

|

14 |

R3-017 |

RN0426-3-1208 |

26 |

8 |

3 |

1.2 |

0.4 |

0.6 |

--- |

||

|

15 |

R3-018 |

RN0414-3-1309 |

14 |

9 |

3 |

1.3 |

0.4 |

0.6 |

--- |

||

|

16 |

R3-019 |

RN0334-3-1035P |

34 |

3.5 |

3 |

1 |

0.3 |

0.6 |

8 |

||

|

17 |

R3-020 |

RN1030-3-2514 |

30 |

14 |

3 |

2.5 |

1 |

1.2 |

--- |

||

|

18 |

R3-021 |

RN0522-3-1608P |

22 |

8 |

3 |

1.6 |

0.5 |

0.8 |

14 |

||

|

19 |

R3-022 |

RN1030-3-20145 |

30 |

14.5 |

3 |

2 |

1 |

1.2 |

--- |

||

|

20 |

R3-023 |

RN08115-3-2006P |

11.5 |

6 |

3 |

2 |

0.8 |

1.1 |

5 |

||

|

21 |

R3-024 |

RN15115-3P |

11.5 |

** |

3 |

** |

1.5 |

2 |

5.5 |

||

|

22 |

R3-025 |

RN08145-3-2085P |

14.5 |

8.5 |

3 |

2 |

0.8 |

0.8 |

6 |

||

|

23 |

R3-026 |

RN10105-3 |

10.5 |

** |

3 |

** |

1 |

1 |

--- |

||

|

24 |

R3-027 |

RN1014-3 |

14 |

** |

3 |

** |

1 |

1 |

--- |

||

|

25 |

R3-028 |

RN0825-3-2520 |

25 |

20 |

3 |

2.5 |

0.8 |

1 |

--- |

||

|

26 |

R3-029 |

RN0829-3-2015 |

29 |

15 |

3 |

2 |

0.8 |

1.2 |

--- |

||

|

27 |

R3-030 |

RN0630-3-1465 |

30 |

6.5 |

3 |

1.4 |

0.6 |

0.8 |

--- |

||

|

28 |

R3-031 |

RN0545-3-1315 |

45 |

15 |

3 |

1.3 |

0.5 |

0.6 |

--- |

||

|

29 |

R3-032 |

RN0630-3-1406 |

30 |

6 |

3 |

1.4 |

1.2 |

0.6 |

--- |

||

|

R4 Series |

|||||||||||

|

1 |

R4-001 |

RN0843-4-2014P |

43 |

14 |

4 |

2.0 |

0.8 |

0.8 |

20 |

||

|

2 |

R4-002 |

RN0843-4-2014P |

43 |

14 |

4 |

2.0 |

0.8 |

1.0 |

20 |

||

|

3 |

R4-003 |

RN0330-4-1515 |

30 |

15 |

4 |

1.5 |

0.3 |

0.6 |

--- |

||

|

4 |

R4-004 |

RN0340-4-1006 |

40 |

6 |

4 |

1 |

0.3 |

0.6 |

--- |

||

|

5 |

R4-005 |

RN1043-4-2514P |

43 |

14 |

4 |

2.5 |

1 |

1.2 |

20 |

||

|

6 |

R4-006 |

RN08285-4-2015 |

28.5 |

15 |

4 |

2 |

0.8 |

1.2 |

|

||

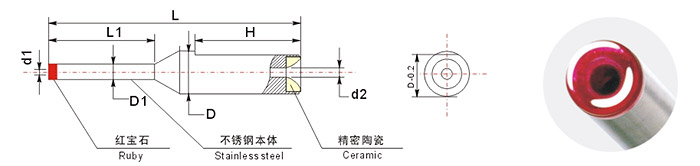

Ruby tiped coil winding nozzle guides(ruby nozzles) also call wire guide tubes,wire guide eyelets,wire guide needles.It is used on coil winding machines and cable machines for wire guide.it is made of stainless stee and ruby by precise processing and combination.The rigidity of ruby is above than level 9 and is just less than that of diamond.Ruby tiped coil winding nozzle guide is a single crystal and can be made with high brightness and cleanness. It can effectively protect paint film and ling term continual work.

1. High Wear Resistance

This is assured by the choice of materials for wear elements possessing. Hardness Value: 1800 ~ 2200Vickers, or 3times that of case hardened steel. Body material is stainless steel for structural supports, not wear-bearing.

2. Scratch-Proofing

Eliminate wire insulation film damage, low friction resistance, stable wire tension. The wire-guiding surfaces are mirror finished by diamond lapping to a surface roughness of 2 -4 micro inches Ra or better, material permit.

3. Straightness and Stiffness

Straightness and Stiffness are defined by the wire exit being concentric and inflexible with respect to the nozzle locating? . In plain terms, the wire should exit from the nozzle concentric to the locating? To within 0.02 mm, with or without load. A geometric characteristic presentation is shown at upper left. Concentricity to within 0.01mm.

4. Precise Exit Radii

Because the coil winding nozzle's Exit Radii governs the angle of the wire exit from one coil to the next, it should be monitored to + / - 0.025 mm. This is done by digital measurement, shown at upper right.